Viskas ūkininkavimui

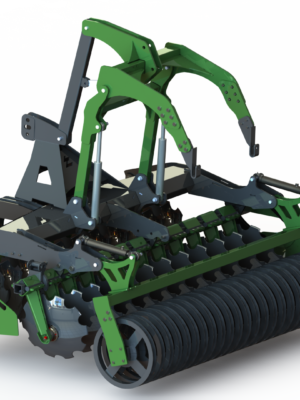

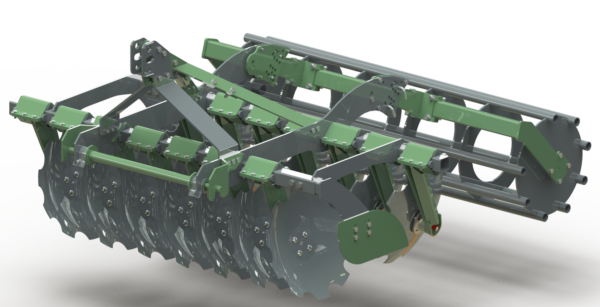

AMON BTL

AMON BTL lengvos konstrukcijos diskiniai skutikai tinkami agregatuoti tiek prie mažų diek prie didelių traktorių..

Naujausio modelio diskiniai skutikai skirti darbui smulkiuose ūkiuose.

Mašina idealiai tinka sėjimo darbams, išlyginimui po arimo ir ražienų laukuose.

Standartinė komplektacija:

Papildoma komplektacija:

|

MODELIS |

BTL 1.0 |

BTL 1.2 |

BTL 1.5 |

BTL 1.8 |

BTL 2.0 |

BTL 2.2 |

|

Darbinis plotis [m] |

1,0 |

1,2 |

1,5 |

1,8 |

2,0 |

2,2 |

|

Svoris* [kg] |

360 |

400 |

500 |

550 |

600 |

650 |

|

Diskų skaičius [vnt.] |

8 |

10 |

12 |

14 |

16 |

18 |

|

Reikalinga traktoriaus galia[AG] |

>25 |

>30 |

>35 |

>40 |

>45 |

>50 |

|

Disko diametras Ø [mm] |

510 |

510 |

510 |

510 |

510 |

510 |

|

*Svoris yra apytikslis ir gali skirtis priklausomai nuo pasirinktos įrangos ir konfigūracijos |

||||||

E-Shop:

AMON BTL – pakabinamas diskinis skutikas

|

MODELIS |

BTL 1.0 |

BTL 1.2 |

BTL 1.5 |

BTL 1.8 |

BTL 2.0 |

BTL 2.2 |

|

KAINA [EUR be PVM] |

2 600 |

2 850 |

3 100 |

3 300 |

3 500 |

3 700 |

|

PAPILDOMA KOMPLEKTACIJA (Kaina EUR be PVM) |

||||||

|

Šoniai atmušėjai |

160 |

|||||

|

Volai |

Volų konfigūracija kainoraščio pabaigoje |

|||||

|

WARNING!!! Below is the „TABLE OF ROLLER ASSEMBLY”, showing the configuration options for individual machine models. |

||||||||||||||

|

WIDTH: |

1,1 |

1,3 |

1,5 |

1,8 |

2 |

2,2 |

2,5 |

2,7 |

3 |

3,5 |

4 |

4,5 |

5 |

6 |

|

MODEL: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tube bar roller Ø 600 |

270 |

310 |

360 |

440 |

490 |

520 |

590 |

650 |

720 |

870 |

960 |

1 060 |

1220 |

1420 |

|

Flat bar roller Ø500 |

Interchangeable with tubular shaft (standard equipment) |

|||||||||||||

|

Flat bar roller Ø600 |

270 |

310 |

360 |

440 |

490 |

520 |

590 |

650 |

720 |

870 |

960 |

1 060 |

1220 |

1420 |

|

Toothed flat bar roller Ø500 |

80 |

90 |

100 |

115 |

130 |

140 |

150 |

160 |

170 |

190 |

200 |

210 |

220 |

230 |

|

Toothed flat bar roller Ø600 |

350 |

400 |

450 |

540 |

600 |

660 |

750 |

800 |

900 |

1 070 |

1200 |

1 350 |

1550 |

1770 |

|

Flat bar-pipe roller Ø500 |

310 |

360 |

400 |

500 |

540 |

590 |

680 |

730 |

800 |

980 |

1070 |

1 210 |

1380 |

1590 |

|

Flat bar-pipe rollerØ600 |

430 |

500 |

560 |

690 |

760 |

840 |

960 |

1 030 |

1130 |

1 380 |

1530 |

1 720 |

1960 |

2270 |

|

Packer roller Ø500 |

380 |

450 |

510 |

610 |

680 |

750 |

840 |

920 |

1020 |

1 220 |

1350 |

1 520 |

1760 |

2030 |

|

Spring roller* Ø470 |

370 |

430 |

500 |

610 |

670 |

730 |

810 |

890 |

980 |

1 220 |

1320 |

1 490 |

1710 |

1960 |

|

Rubber roller Ø500 |

960 |

1 110 |

1 270 |

1 530 |

1710 |

1 860 |

2 130 |

2 290 |

2530 |

3 060 |

3400 |

3 800 |

4420 |

5090 |

|

Steel ring roller Ø610 |

– |

– |

– |

– |

– |

– |

2 020 |

2 190 |

2400 |

2 950 |

3250 |

3 650 |

4050 |

4840 |

|

V-ring roller* Ø500 |

480 |

560 |

650 |

790 |

860 |

960 |

1 070 |

1 160 |

1290 |

1 570 |

1720 |

1 930 |

2230 |

2570 |

|

V-ring roller* Ø600 |

550 |

650 |

740 |

920 |

980 |

1 090 |

1 220 |

1 340 |

1470 |

1 770 |

1960 |

2 190 |

2550 |

2940 |

|

T-ring roller* Ø500 |

570 |

680 |

770 |

920 |

1030 |

1 130 |

1 290 |

1 380 |

1530 |

1 840 |

2050 |

2 300 |

2650 |

3060 |

|

T-ring roller* Ø600 |

650 |

700 |

860 |

1 060 |

1160 |

1 290 |

1 450 |

1 580 |

1750 |

2 120 |

2330 |

2 610 |

3030 |

3490 |

|

U-ring roller* Ø500 |

590 |

690 |

790 |

960 |

1 035 |

1 150 |

1 300 |

1 420 |

1570 |

1 900 |

2080 |

2 350 |

2700 |

3130 |

|

U-ring roller* Ø600 |

660 |

780 |

890 |

1 070 |

1200 |

1 320 |

1 490 |

1 610 |

1770 |

2 140 |

2380 |

2 680 |

3100 |

3560 |

|

Light U-ring roller Ø500 |

– |

– |

– |

– |

– |

– |

– |

– |

1350 |

1 700 |

– |

– |

– |

– |

|

Crosskill roller Ø400 |

800 |

930 |

1 070 |

1 290 |

1440 |

1 580 |

1 800 |

1 930 |

2140 |

2 570 |

2880 |

3 220 |

3720 |

4290 |

|

Crosskill rollerØ500 |

910 |

1 070 |

1 220 |

1 480 |

1650 |

1 810 |

2 050 |

2 190 |

2450 |

2 930 |

3280 |

3 680 |

4260 |

4890 |

|

Tandem crosskill roller Ø400 |

– |

– |

– |

– |

– |

– |

– |

– |

– |

– |

6050 |

6 760 |

7740 |

8860 |

|

Smooth tubular roller Ø500 |

270 |

310 |

360 |

440 |

490 |

520 |

– |

– |

– |

– |

– |

– |

– |

– |

|

Scrapers for roller: spring, U-ring, V-ring, T-ring,spring |

190 |

200 |

220 |

230 |

260 |

270 |

290 |

310 |

340 |

380 |

430 |

520 |

570 |

660 |

|

* – standard rollers are not equipped with scrapers (roller cleaners) |

||||||||||||||

|

XP-PRO |

Additional payment for tandem rollers in the XP-PRO system |

||||||||||||

|

|

MODEL |

Intended for: |

Width: |

2 |

2,2 |

2,5 |

2,7 |

3 |

3,5 |

4 |

4,5 |

5 |

6 |

|

|

Tube bar roller Ø500 + Flat bar rollerØ400 |

AT, BTB, BTHX,BTH, M,AS, BTA, |

|

1190 |

1220 |

1290 |

1350 |

1420 |

1570 |

1660 |

1760 |

1930 |

2120 |

|

|

Tube bar roller Ø500 + tube bar rollerØ500 |

|

|

1240 |

1290 |

1350 |

1420 |

1470 |

1610 |

1720 |

1830 |

1990 |

2170 |

|

|

Flat bar roller Ø500 + Flat bar roller Ø500 |

|

|

1240 |

1290 |

1350 |

1420 |

1470 |

1 610 |

1720 |

1830 |

1990 |

2170 |

|

|

V-ring roller Ø500 + V-ring roller Ø500 |

|

|

2300 |

2470 |

2580 |

2860 |

3100 |

3580 |

3850 |

4260 |

4790 |

5400 |

|

|

T-ring roller Ø500 + T-ring roller Ø500 |

|

|

2610 |

2820 |

3090 |

3250 |

3520 |

4070 |

4480 |

4930 |

5570 |

6270 |

|

|

U-ring roller Ø500 + U-ring roller Ø500 |

|

|

2650 |

2830 |

3110 |

3300 |

2880 |

3830 |

4510 |

4990 |

5640 |

6400 |

|

BTA/CBTHD |

Additional payment for tandem rollers for models: CBTHD and BTA |

||||||

|

|

MODEL |

Intended for: |

Width: |

4 |

4,5 |

5 |

6 |

|

|

Tube bar roller Ø500 + Toothed flat bar roller Ø400 |

BTA |

|

1 880 |

1 980 |

2 140 |

2 330 |

|

|

Tube bar roller Ø600 +Tube bar roller Ø600 |

CBTHD |

|

2 030 |

2 130 |

2 300 |

2 490 |

|

|

V-ring roller Ø600 + V-ring roller Ø600 |

BTA, CBTHD |

|

4 450 |

4 900 |

5 520 |

6 200 |

|

|

T-ring roller Ø600 + T-ring rollerØ600 |

BTA, CBTHD |

|

5 100 |

5 640 |

6 390 |

7 200 |

|

|

U-ring roller Ø600 + U-ring roller Ø600 |

BTA, CBTHD |

|

5 230 |

5 750 |

6 490 |

7 320 |

|

Machinesmodel: |

CA |

CAX |

AS |

AUS |

ATB |

LBT |

BTL |

BTW |

BTH |

BTHX |

CBTHD |

BTA |

BTB |

GV |

GM |

M |

CAS |

|

Model: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tube bar roller Ø500 |

● |

● |

● |

● |

● |

|

● |

● |

● |

● |

|

● |

● |

● |

● |

● |

● |

|

Tube bar roller Ø600 |

|

● |

|

|

|

● |

|

|

● |

● |

● |

● |

● |

● |

|

● |

|

|

Flat bar rollerØ500 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

● |

|

● |

● |

● |

|

Flat bar rollerØ600 |

|

● |

|

|

|

● |

|

|

● |

● |

|

● |

● |

|

|

● |

|

|

Toothed flat barrollerØ500 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

● |

|

● |

● |

● |

|

Toothed flat barroller Ø600 |

|

● |

|

|

|

● |

|

|

● |

● |

|

● |

● |

|

|

● |

|

|

Flat bar-piperoller Ø500 |

● |

● |

● |

|

● |

● |

|

● |

● |

● |

|

|

● |

|

● |

● |

|

|

Flat bar-piperoller Ø600 |

|

● |

|

|

|

● |

|

|

● |

● |

|

|

● |

|

|

● |

|

|

Packer roller Ø500 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

● |

● |

● |

● |

● |

|

|

Spring roller*Ø470 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|

|

● |

|

|

● |

● |

|

Rubber rollerØ500 |

|

● |

● |

● |

● |

● |

|

|

● |

● |

|

● |

● |

● |

● |

● |

|

|

Steel ring rollerØ610 |

|

● |

|

|

|

● |

|

|

● |

● |

● |

● |

● |

● |

● |

● |

|

|

V-ring roller*Ø500 |

|

● |

● |

|

● |

● |

|

● |

● |

● |

|

|

● |

● |

● |

● |

|

|

V-ring roller*Ø600 |

|

● |

|

|

|

● |

|

|

● |

● |

● |

● |

● |

|

|

● |

|

|

T-ring roller*Ø500 |

|

● |

● |

|

● |

● |

|

● |

● |

● |

|

|

● |

● |

● |

● |

|

|

T-ring roller*Ø600 |

|

● |

|

|

|

● |

|

|

● |

● |

● |

● |

● |

|

|

● |

|

|

U-ring roller*Ø500 |

|

● |

● |

|

● |

● |

|

● |

● |

● |

|

|

● |

● |

● |

● |

|

|

U-ring roller*Ø600 |

|

● |

|

|

|

● |

|

|

● |

● |

● |

● |

● |

|

|

● |

|

|

Light U-ring rollerØ500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

● |

|

|

Crosskill rollerØ400 |

● |

● |

|

● |

● |

● |

|

● |

● |

● |

|

|

● |

|

|

● |

|

|

Tandem crosskillroller Ø400 |

● |

● |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Crosskill rollerØ500 |

|

|

|

|

● |

● |

|

|

● |

● |

|

● |

● |

|

|

● |

|

|

Smooth tubularroller Ø500 |

|

|

|

|

|

● |

|

● |

|

|

|

|

|

|

|

|

|

|

TABLE OF ROLLER ASSEMBLY |

|||||||||

|

Machines model: |

CAX |

AS |

BTH |

BTHX |

CBTH |

BTA |

BTB |

M |

|

|

XP-PRO |

Tube bar roller Ø500 + Flat bar roller Ø400 |

● |

● |

● |

● |

|

|

● |

● |

|

|

Tube bar roller Ø500 + Tube bar roller Ø500 |

|

|

● |

● |

|

|

● |

● |

|

|

Flat bar roller Ø500 + Flat bar roller Ø500 |

|

|

● |

● |

|

|

● |

● |

|

|

V-ring roller Ø500 + V-ring roller Ø500 |

|

|

● |

● |

|

|

● |

● |

|

|

T-ring roller Ø500 + T-ring roller Ø500 |

|

|

● |

● |

|

|

● |

● |

|

|

U-ring roller Ø500 + U-ring roller Ø500 |

|

|

● |

● |

|

|

● |

● |

|

BTA/CBTHD |

Tube bar roller Ø500 + Toothed flat barroller Ø400 |

|

|

|

|

|

● |

|

|

|

|

Tube bar roller Ø600 + Tube bar roller Ø600 |

|

|

|

|

● |

● |

|

|

|

|

V-ring roller Ø600 + V-ring roller Ø600 |

|

|

|

|

● |

● |

|

|

|

|

T-ring roller Ø600 + T-ring roller Ø600 |

|

|

|

|

● |

● |

|

|

|

|

U-ring roller Ø600 + U-ring roller Ø600 |

|

|

|

|

● |

● |

|

|